for high compression needs

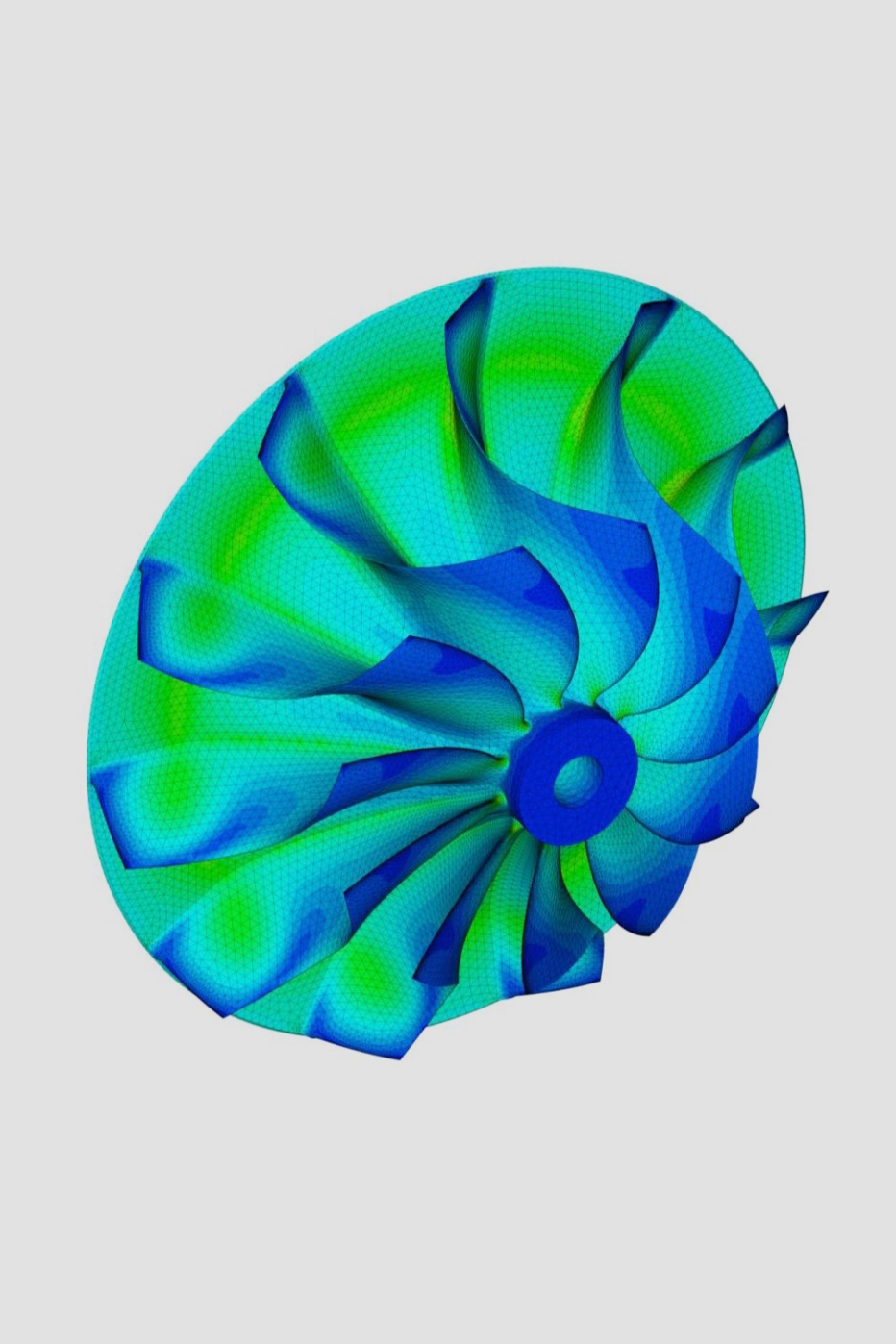

JCL turbocompressors are used wherever there is a need for high compression: in the gas, chemicals, air separation, metal or oil industries. We develop our radial compressors and axial compressors according to your specific requirements: no standard designs are available from us. Each of our machines is an individual creation. Accordingly, we are able to offer flexible control system, package and auxiliary system designs. Of course, we also adapt our machines to all possible gas compositions. Neither hydrogen nor acid gas processes pose a problem to us. Our expertise and experience particularly come into play in manufacturing highly-specific turbocompressors for complex processes in which high efficiency and extreme durability are needed.

Are you looking for a turbocompressor?

Then arrange an appointment with us!

We'll step up the pressure for your project!

Highly-efficient turbocompressors pressurise fluids to high levels

Not all turbocompressors are the same: compressors are used in processes as varied as boosting the pressure in gas pipelines, as blowers in blast furnaces and steelworks, for liquefying gases, in chemical plants and refineries or in cooling systems and heat pumps. The design, efficiency and material requirements of each of these applications differ. Our engineers are able to develop the appropriate turbocompressor for each requirement profile. We don't shy away from technical challenges. Quite the opposite: they motivate us to perform even better. You've come to the right place if you're looking for an efficient, durable solution for your specific application rather than industrial off-the-peg products. With our team, we deliver a bespoke, high-quality product that beats the competition in terms of prices.

We offer compressors for the following processes

and applications, among others:

We manufacture these turbocompressors for you:

We do not measure our success by the number of our orders, but by the satisfaction of our customers. Our work for you is only completed when the turbocompressor is installed on site and delivers the output specified by you. Our dedication is evident in each and every step of the work required to accomplish this: from expert, goal-oriented advice and innovation-driven development and design engineering up to and including final commissioning. We don't just view ourselves as a manufacturer, but as a partner that wants to enjoy success together with its customers.

Your path to a JCL turbocompressor