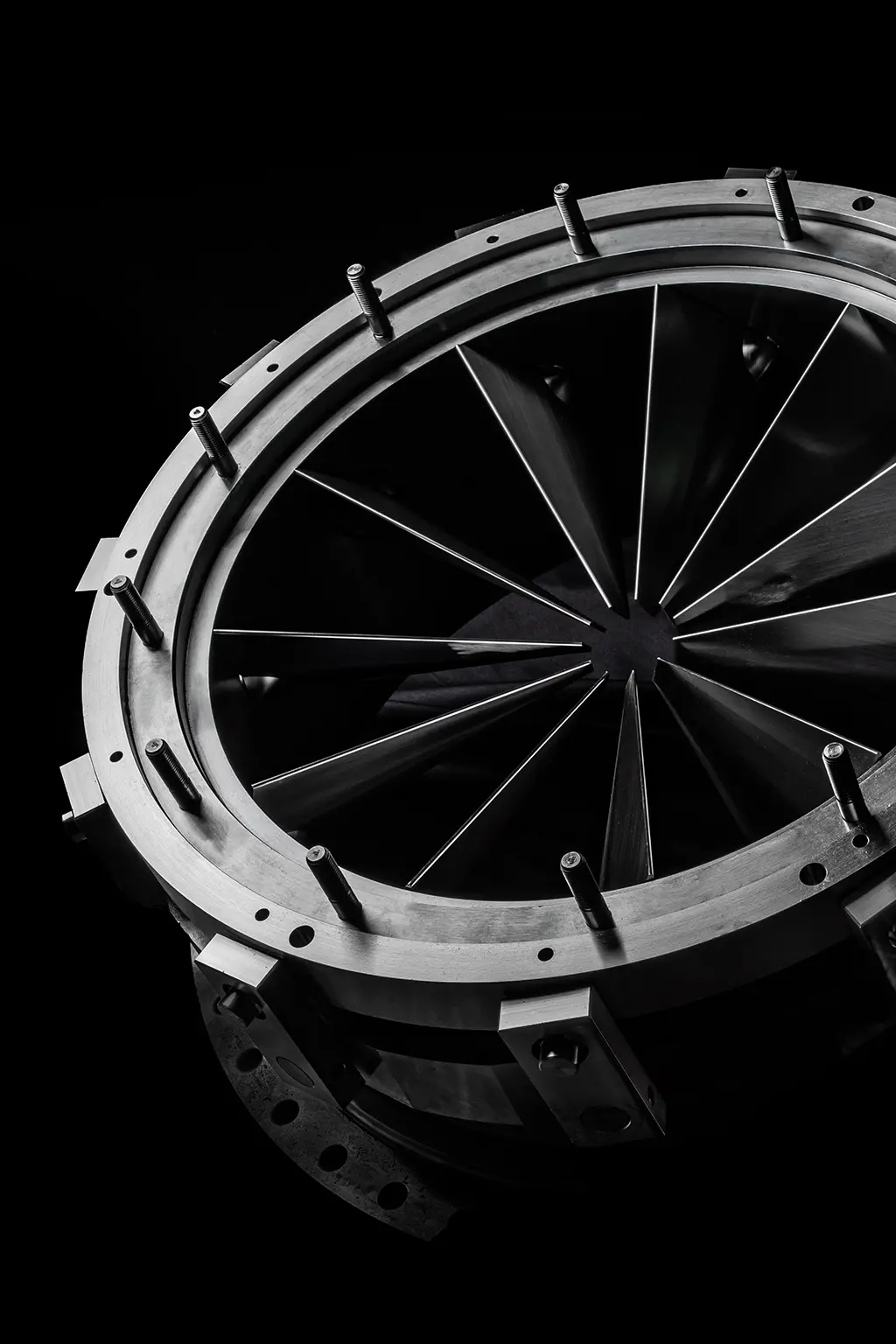

Turbomachines – turboexpanders or radial expansion turbines, NCG expanders and turbocompressors – for use in the oil industry, the energy and gas industries, the air separation and chemicals industries as well as in metalworking are our core competence. Our engineers manufacture powerful, durable turboexpanders and turbocompressors for your individual, specific processes. Years of experience in the industry, a wealth of expertise in development as well as our extensive drive to innovate and lean process management enable us to beat our competitors on prices – and surpass them in terms of quality.

Are you looking for a strong partner that can supply you with bespoke machines and spare parts, one that can increase your plant's productivity and efficiency, and one that will prevent costly downtimes with its commitment and hands-on mentality in the worst case scenario?

'It's best to buy large, powerful and complex machines from a traditional manufacturer.' – This widespread conviction is entirely understandable, but the sheer size of the prime market leaders often proves disadvantageous in daily operations: instead of getting directly through to your contact person, you spend a long time on hold. Innovation and individuality are replaced by standardised product lines. And in the worst-case scenario, you are confronted with sluggishness and inflexibility when quick decisions, agility and flexibility are needed.

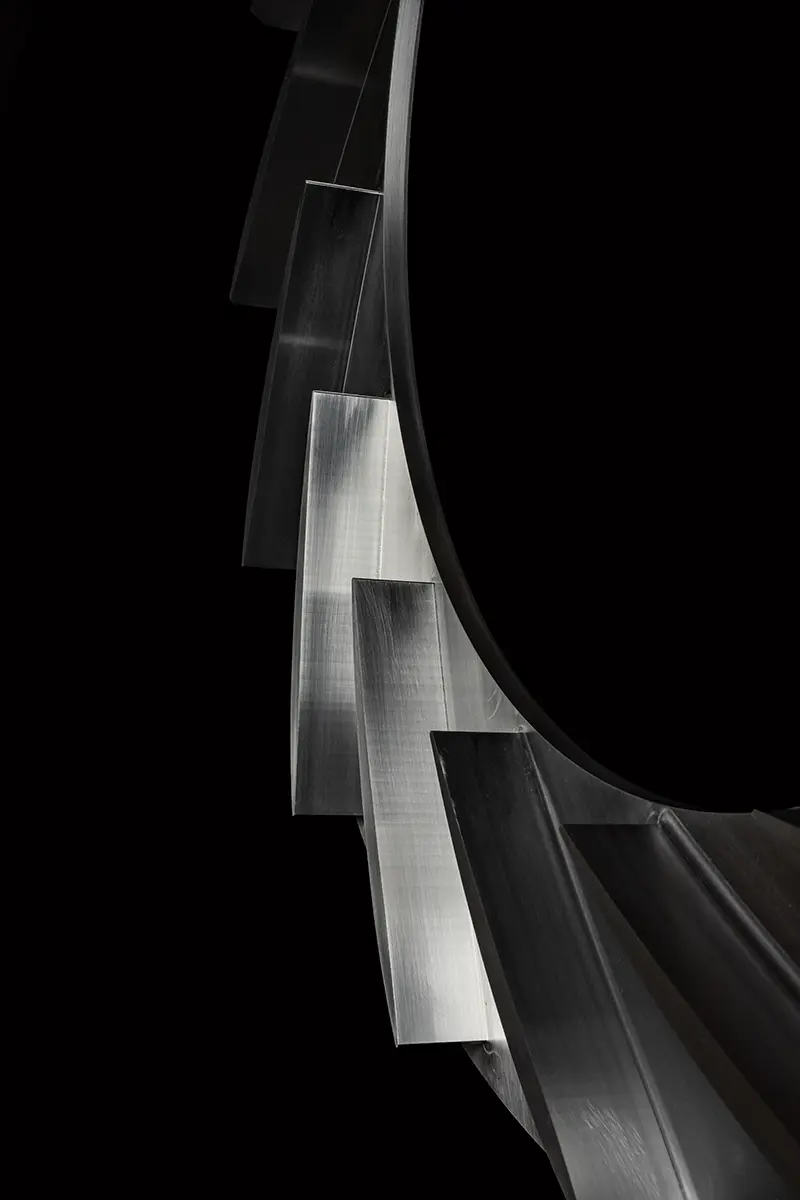

Developing and designing turboexpanders and radial expansion turbines are our great passion. Our expertise particularly shows when it comes to making processes more efficient, because we can find optimisation potential in even the smallest of details. We will supply you with turboexpanders that are tailored precisely to your requirements, which only cause minimal costs per additional kilowatt and which ensure the environmentally sound operation of your plant.

performance under high pressure

Companies in the steel or metal production industries, the chemicals industry and the oil and gas industries are reliant on highly-efficient compressors designed for high outlet pressures and volumetric flows. Aimed specifically at your individual processes and requirements, JCL designs, manufactures and installs radial compressors and single-shaft compressors with or without integral gearing with an eye for that all-important detail. Each of our turbocompressors is unique, because we design it specifically for you.

We supply spare parts in OEM quality for your turbomachines – no matter which brand. In the event of an overhaul, maintenance or machine failure, we optimise, develop, design, supply and install critical spare parts and spare parts for maintenance or commissioning according to your needs and requirements. We not only promise you an adequate replacement, we also promise that your machines will run just as as reliably and efficiently as they did before.

When maintenance is needed, when a malfunction occurs or when downtime is looking likely, it's good to have a partner that is on hand to help you quickly and without a lot of red tape. Our technicians respond within one day and are often able to rectify faults by remote diagnosis on the telephone. If on-site intervention is needed, our team is usually able to start work within 72 hours.

With a small, but highly-qualified and motivated team, JCL has succeeded in establishing itself on the market as a genuine alternative to the big players in just a few years. Our core competence – individually developed turbomachines for highly-specific process requirements – has been demonstrated in a number of flagship projects that we're particularly proud about.

successful

alternative to the

industry leaders

As a manufacturer of turboexpanders and turbocompressors as well as appropriate spare parts, JCL has been a genuine alternative to the established manufacturers since the company was set up in 2018. Over the course of his 20-year career, Lennard Lischke, company founder and managing director, acquired experience as a project manager for new machines at Atlas Copco for ten years, among other positions. He knows exactly what his customers want – and where the major players often fail. This is precisely where he comes into play with JCL: with top-flight engineering and service that focuses first and foremost on customer satisfaction.